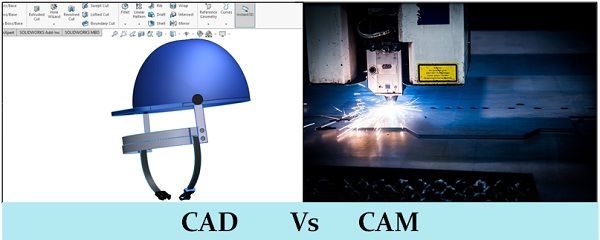

CAD (Computer Aided Drawing/Drafting) and CAM (Computer Aided Manufacturing) are computer technologies used for mainly product designing and manufacturing purposes where former is used in designing of the product through some designing software while latter involves software for controlling the machines in the industries such as CNC machines.

CAD (Computer Aided Drawing/Drafting) and CAM (Computer Aided Manufacturing) are computer technologies used for mainly product designing and manufacturing purposes where former is used in designing of the product through some designing software while latter involves software for controlling the machines in the industries such as CNC machines.

CAD and CAM are the steps included in the manufacturing of a product. Let us understand the difference between CAD and CAM through the given comparison chart.

Content: CAD Vs CAM

Comparison Chart

| Basis for comparison | CAD | CAM |

|---|---|---|

| Basic | CAD is the implementation of digital computers in engineering design and production. | CAM is the implementation of computers in transforming engineering designs into end products. |

| Involved processes | Definition of a geometric model, definition translator, geometric model, interface algorithm, design and analysis algorithms, drafting and detailing, documentation. | Geometric model, process planning, interface algorithm, NC programs, inspection, assembly and packaging. |

| Requires | Design conceptualization and analysis. | Control and coordination of the necessary physical processes, equipment, materials, and labour. |

| Softwares | AutoCAD, Autodesk Inventor, CATIA, SolidWorks | Siemens NX, Power MILL, WorkNC, SolidCAM |

Definition of CAD

CAD (Computer Aided Design) system generate accurately, scaled mathematical models based on user input. Individual models are then integrated as components of an assembly to create the final product through which exact fit of the parts can be checked. Fully furnished 3D models of parts and whole assemblies for designs can be build using 3-Dimensional CAD software. Even the created designs can be examined virtually from any angle before manufacturing the product.

Definition of CAM

CAM (Computer Aided Manufacturing) is evolving as a central element in many productions. It includes a broad range of process to be carried out automatically such as cutting, turning, milling, routing, heat cutting, engraving and even printing of solid materials. After designing and analysing a product, it is manufactured where computers are involved in manufacturing like to checking whether the product can be made or made by which process, and how much time it is going take.  In simple words computer system used in planning, managing and controlling the operation of manufacturing plant is called CAM. It actually conserves the material to some extent by careful placing of the components.

In simple words computer system used in planning, managing and controlling the operation of manufacturing plant is called CAM. It actually conserves the material to some extent by careful placing of the components.

Key Differences Between CAD and CAM

- Computer-aided design (CAD) involves the use of computers for transforming the elementary idea of product into a detailed engineering design. The evolution includes the creation of product’s geometric models, which can further be manipulated, analyzed and refined. On the other hand, Computer-aided manufacturing (CAM) involves the use of computers for assisting managers, manufacturing engineers, and production workers by automating production tasks and it also controls machines and systems.

- CAD comprise of processes such as defining the geometric model and translating the definition, interface, design, and analysis algorithm, drafting, detailing and at last documentation. As against, CAM involves processes such as geometric modelling, numerical control programs, interface algorithms, inspection, process planning, assembly and packaging.

- The CAM system requires control and coordination of the physical process, equipment, material, and labour whereas CAD requires product design conceptualization and analysis.

- There is numerous CAD software, for example, AutoCAD, Autodesk Inventor, CATIA etcetera. In contrast, Siemens NX, Power MILL, WorkNC, SolidCAM are some the examples for CAM software.

Advantages of CAD

- Minimizes the requirement for huge numbers of an expensive draftsman in designing of a product.

- It can be used directly in order to generate cutting data for CNC machines.

- Scaling, re-scaling modification in drawings and models is easier and automatic and accurate.

- Storage and retrieval of models is easier.

- Design data can be shared in computerised manufacturing management systems.

- Precise 3D models can be examined before making expensive materials.

- It increases the speed of production and requires less labour.

- Multiple copies can be stored, printed and shared electronically, which eliminates the need for storing large paper drawings.

Advantages of CAM

- Manufacturing requires minimum supervision and can be accomplished during unsocial work hours.

- Manufacture is less labour intensive and saves labour cost.

- Machines are accurate, and manufacturing can be repeated consistently with large batches.

- Error occurrence is negligible, and machines can run continuously.

- Prototype models can be prepared very speedily for elaborated inspection before finalising designs for manufacture.

- Virtual machining can be used to evaluate machining routines and outcomes on the screen.

Disadvantages of CAD

- Power cuts and viruses can be problematic for the computerised system.

- Industrial versions of the software could be very expensive to buy especially for the startup costs.

- Traditional drafting skills will be lost as they become unnecessary.

- Expensive training would be required to use the software, which can be time-consuming and costly.

Disadvantages of CAM

- It requires high initial investment and start-up cost.

- Machine maintenance is also costly.

- May result in loss of a workforce with high-level manual skill.

- To assure proper tooling and set up procedures it needs highly trained operatives and technicians.

Conclusion

Computer aided designing/drafting (CAD) and Computer-aided manufacturing (CAM) are closely related terms used where computers are involved in the design and manufacturing processes of a product in CNC industries.

Siddharth says

Good explanation…doubts are cleared

Mayur says

very good information… nice post

SophiaMourphy says

NICE! Very appreciated article. Very good explanation of all steps like compression and advantages etc. Really i get a lot of information about CAD and CAM and get key differences between CAD and CAM. The blog is shareable on social sites.

Magdalena paulus says

This indeed engaged me in useful and shorten information on CAD and CAM. Really appreciate the fact that I learned the difference between them.

Taylor Hicken says

I appreciated it when you shared that the manufacturing of products involves the use of CAD and CAM. It is crucial to find the right software that can aid in the process. I would like to think if a company needs to use CAD and CAM, it should consider working with a reliable service that can provide the software.